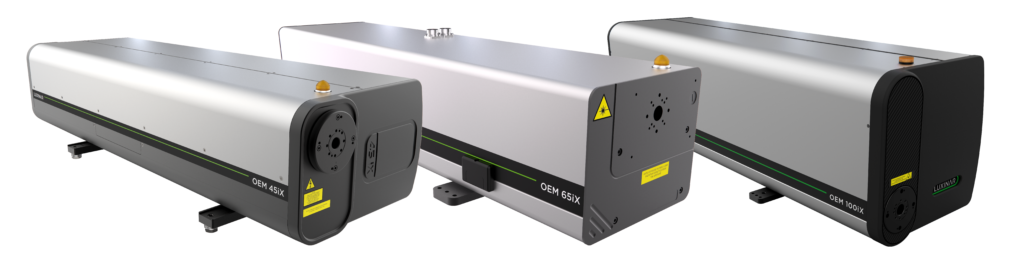

- Laser type: CO2

- Wavelenght: 10 600 nm

- Output power: 10-8000 W

- Aplications: cutting, welding, machining of non-metallic materials

- Industries: metalworking, automotive, tobacco, glass, packaging, plastics

The oldest type of industrial lasers used for material processing is the CO2 laser, which is characterized by high reliability, robustness, and excellent beam quality. The development of laser technologies has meant that high-power lasers, i.e. above 1 kW, are gradually being replaced by fiber lasers, but in the low-power range they still represent a very large market area. In our applications, lasers ranging from 10 W to as high as 8,000 W are used, dedicated to processes such as

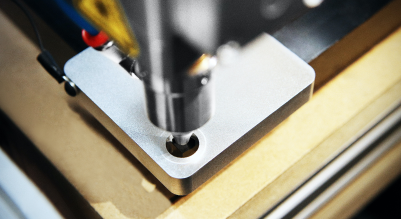

- 2D and 3D cutting of stainless and low-carbon steel materials

- welding of stainless and low-carbon steel

- welding of tubes and profiles

- working of non-metallic materials: plastics, wood, textiles, leather, paper, rubber, film

By design, in a CO2 laser, the active medium is a gaseous mixture consisting of helium, 10-20% carbon dioxide, 10-20% nitrogen, a few percent hydrogen and xenon. The CO2 molecule absorbs the energy supplied from outside, so that it goes into a high state, and then emits a beam of electromagnetic radiation with a length of 10.6 micrometers, which is the basis of the laser action.Modern DC-type lasers have resonators made of two mirrors, including one semi-permeable, and fed electrodes that generate a high-frequency electromagnetic field. Stimulation of the gas mixture causes the laser action and temperature increase of the substance, and its dissipation is carried out by means of heat diffusion from the medium to the electrodes combined with water cooling. In such a design, there are no additional systems to ensure gas circulation, making maintenance and operation even simpler. DC-type lasers generate the highest quality beam, up to K > 0.9, with the best efficiency among CO2 lasers.