- Types of machining: surface cleaning, surfacing, welding, marking

- Machined materials: metals and plastics

- Purpose of machining: chemical-free cleaning, low-cost repair of material damage, crack-free welding, product identification

- Adventages: can be easily automated, contactless, high machining speed, small heat affected zone, high quality, repeatability and machining accuracy

Surface cleaning

Resurfacing

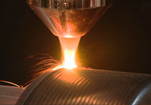

Welding

Marking

Laser marking by annealing is a technique that takes advantage of changes in the color of a material’s surface due to temperature and the oxidation phenomenon that then occurs. The small diameter of the laser beam makes it possible to locally spot heat the material to a temperature at which the color change of the outer layer of the material occurs. The marking thus produced is characterized by high contrast and accuracy while maintaining surface continuity.

An alternative method to annealing is engraving, during which a laser beam vaporizes a portion of the material. The resulting symbols and marks reach a depth of several micrometers and are resistant to abrasive wear, so they remain clearly visible at all times. The ease of making designs, as well as their repeatability and accuracy, make laser engraving an ideal solution for both unit and high volume production.