- Laser type: with an ultra-short pulse

- Wavelength: 343-1030 nm

- Output power: 1,5-100 W

- Pulse frequency: 1-1000 kHz

- Aplications: cutting,drilling, marking, structuring and ablation

- Industries: electronics, photovoltaics, aerospace, automotive, semiconductors, glass, medical technology

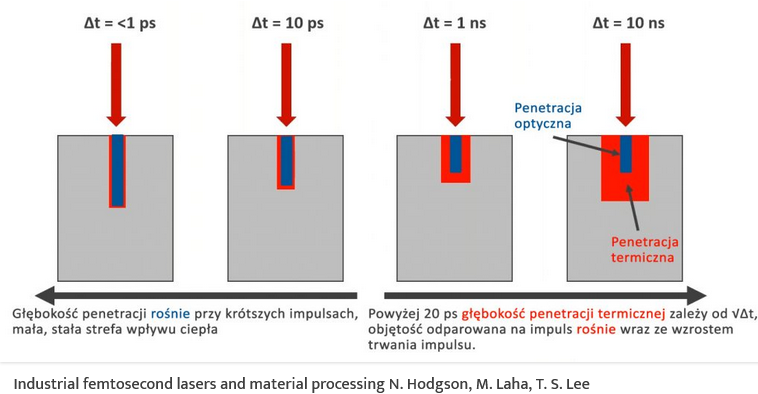

Very demanding micromachining applications use lasers with very short pulses, ranging from 100 femtoseconds to 10 picoseconds. Reducing the pulse duration increases the depth of energy penetration and reduces energy dissipation. This allows processing at a rate faster than it takes for heat to diffuse inside the material. This is known as “cold processing” because the temperature of the component does not rise during the process, ensuring that the properties of the substance are unchanged and there is no heat-affected zone.

Ultra-short pulse lasers are ideal for

- cutting

- drilling

- marking

- structuring and ablation processes on the surfaces of a variety of materials

.