- Types of machining: welding of plastic

- Machined materials: plastic

- Adventages: minimal thermal and mechanical stress, high quality and durability of the weld, speed, aesthetics

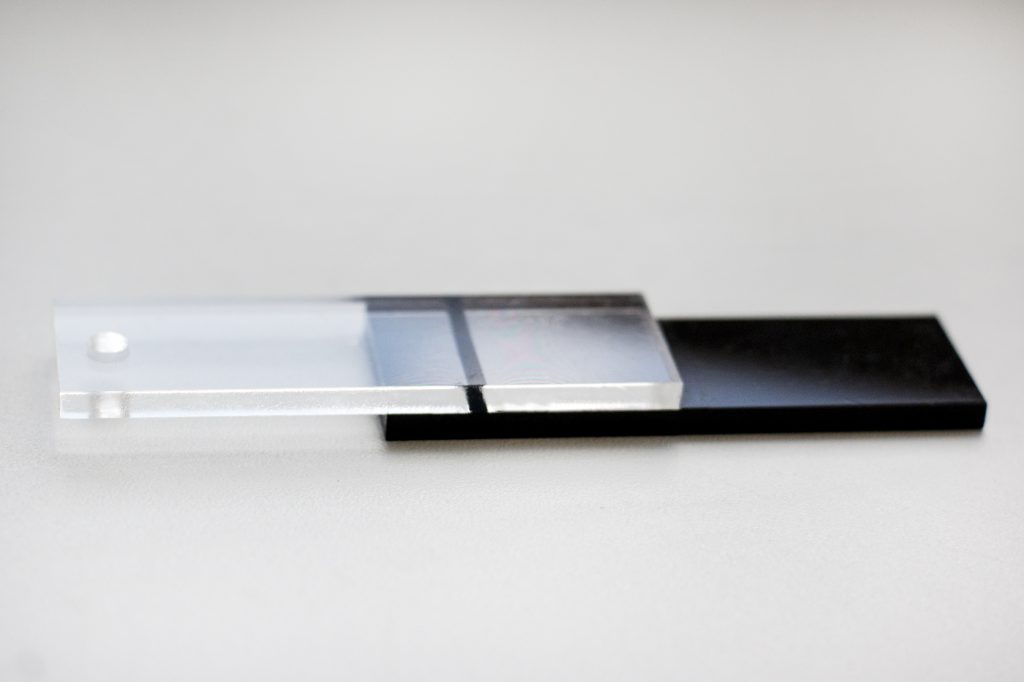

Laser welding of plastic, is the process of joining two or more parts by using energy generated by a laser beam. Unlike traditional methods such as gluing or vibration or ultrasonic welding, laser welding is based on direct heating of the joining areas using intense laser radiation. As a result of the concentrated heat, the materials are melted in the designated areas, and once cooled, a permanent connection is made. This method of transmissive ‘overlap’ joining of materials requires the ‘top’ material to have adequate transmissivity for a specific wavelength of laser radiation, while the ‘bottom’ component should have adequate absorptivity. You can read more on this subject here.

Advantages

- Precision and control: Laser welding allows control over the amount of heat delivered, leading to precise and uniform joints. This is especially important for delicate or complex parts that require a tight joint. The process can be controlled by using, for example, a pyrometer or LVDT sensors. This makes it possible to compensate (to some extent) for imperfections in the plastic

- No intermediate materials: Unlike other joining methods, laser welding does not require additional adhesives or binders.

- Time and Efficiency: The laser welding process is typically fast and efficient, contributing to production efficiency.

- Esthetics: Joints achieved by laser welding are typically aesthetically pleasing, with no obvious joint marks or irregularities. The process generates an ‘invisible weld’.

- Limited deformation: Thanks to the precise heating of the joining areas, material distortion is minimized, which is important for components that require the maintenance of precise dimensions.

- Flexibility: Depending on the appropriate tools and fictures prepared in the machine and the optical set of the laser system, it is possible to change the manufactured components flexibly and quickly.

The method of laser welding of plastics has a wide range of applications:

- Motorcraft: In automotive component manufacturing, laser welding is used to join interior components, lamp housings or fuel tanks. Also, electronic components are sealed in plastic housings and then laser welded.

- Medical: In the medical industry, laser welding can be used to join components of apparatus, implants or electronics working inside the human body.

- Electronics: Laser welding has the advantage over ultrasonic welding that it does not adversely affect electronic components.