- Types of processing: laser cutting (gas, by melting, sublimation)

- Machined materials: metallic materials, glass, composites, plastics, wood, semiconductors

- Material thickness: up to 40 mm

- Advantages: versatility, high process speed, contactless, high precision due to small beam diameter

Laser cutting

Photo gallery

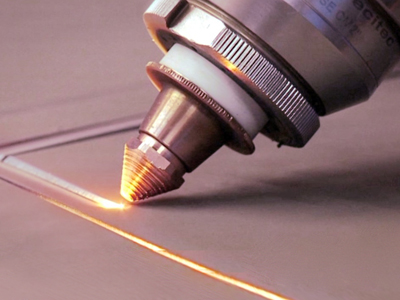

Gas cutting

Cutting by smelting

Laser cutting by melting is a method used for materials that melt. As in the gas-cutting process, the special design of the laser head makes it possible to introduce compressed inert gas (nitrogen, helium or argon) into the crater formed by the laser, which results in the blowing out of the molten substance and prevents oxidation of the processed edges.

Due to the chemical inertness of the gas, no combustion takes place, so the laser beam is the only source of energy in the melting process. This means that the operating speed is closely related to the thickness of the material being cut. For thin sheets, it is similar to that of gas cutting. Thick sheets, on the other hand, require a much lower operating feed rate than in gas cutting.

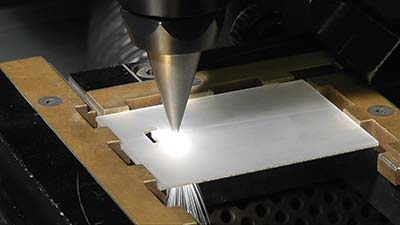

Sublimation cutting

Sublimation cutting is used wherever high edge quality and high precision processing are required. The laser beam heats the material above the evaporation temperature, ensuring only minimal melting. As a result of sublimation, high pressure is created in the hole, leading to the molten substance being ejected outside the working area. To prevent oxidation of the edges of the workpiece, shielding gases such as helium, argon or nitrogen are used.

Heating the material above the vaporization temperature requires a high power density of the laser beam, making the process speed much slower than with other cutting techniques. As a result, the method in question is most often used for cutting materials with a low vaporization temperature, such as organic substances, plastics or wood. For metallic materials, it is used only when very high precision cutting is required, such as in medicine.