The CO2 laser, or carbon dioxide laser, is one of the most versatile and effective tools used in industry. Since their invention in the 1960s, CO2 lasers have revolutionized many sectors, from materials processing to medicine, but their main use is in industry. In this article, we will discuss the applications of CO2 lasers, what they are and how they work, and the benefits they bring to various industries.

How do CO2 lasers work?

A CO2 laser is a type of gas laser in which the active medium is a mixture of gases, mainly carbon dioxide (CO2), nitrogen (N2) and helium (He). In the process of generating the laser, electrical energy excites the gas molecules, causing the emission of laser light with a wavelength of about 10.6 micrometers. This is infrared radiation, which has particularly high efficiency in materials processing.

Industrial applications of CO2 lasers

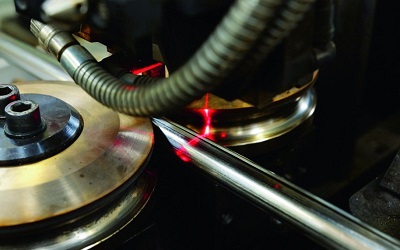

1. Cutting and metalworking

CO2 lasers are widely used for cutting and processing various materials, including metals. Thanks to the precise focus of the laser beam, it is possible to cut stainless steel, aluminum and other metals with high accuracy. This technology makes it possible to achieve clean and smooth edges without the need for additional processing, which significantly increases the efficiency of production processes.

2. Engraving and marking

CO2 lasers are also widely used for engraving and marking a variety of materials, such as wood, glass, ceramics and plastics. They can produce permanent and precise markings, which is extremely important in the electronics, automotive and packaging industries.

3. Laser welding

Welding with CO2 lasers is becoming increasingly popular in industry, especially where precision and clean joints are required. These lasers make it possible to weld thin metal sheets and create complex shapes, which is not possible with traditional welding methods.

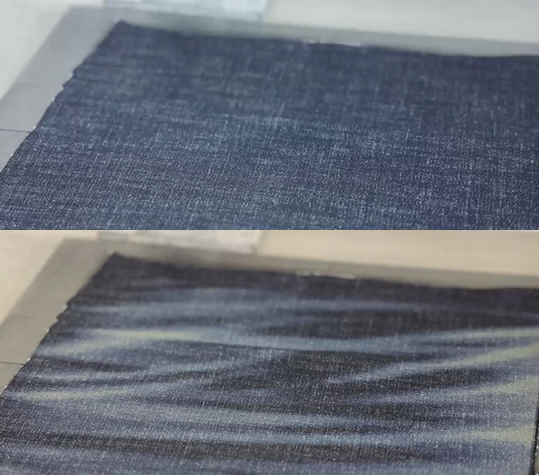

4. Machining of non-metallic materials

CO2 lasers are indispensable for processing non-metallic materials such as fabrics, leather, paper and others. Their use allows for fast and precise cutting and engraving, which is especially appreciated in the textile and fashion industries.

Advantages of CO2 lasers in industry

1. High precision and quality machining

One of the biggest advantages of CO2 lasers is their ability to process materials with extreme precision. Thanks to the concentrated laser beam, it is possible to achieve very fine details and smooth edges, resulting in high-quality end products.

2. Speed and efficiency

CO2 lasers allow very fast cutting and processing of materials, which significantly increases the efficiency of production processes. Compared to traditional methods, laser processing technologies are much faster, which reduces production time and costs.

3. Versatility

CO2 lasers are extremely versatile and can be used to process a wide range of materials. From metals to plastics, these lasers are able to meet a wide variety of industrial requirements, making them an ideal tool for many sectors.

4. Process automation

With the ability to integrate with CNC (Computer Numerical Control) systems, CO2 lasers can be fully automated. This allows precise control of the machining process, minimizing errors and increasing production efficiency.

CO2 laser technology is constantly evolving, opening up new possibilities for their use in industry. Work on increasing energy efficiency and innovative solutions for cooling and laser beam management will make CO2 lasers even more versatile and economical in the future.

CO2 lasers are extremely versatile and efficient tools that play a key role in modern industry. Their ability to precisely process a wide range of materials, their high speed and their ability to automate processes make them indispensable in many sectors. Through continuous innovation and technology development, CO2 lasers will continue to revolutionize the industry, bringing new benefits and opportunities.