Automotive engineering is undergoing a dynamic transformation. The propulsion concepts used to date are slowly being challenged – those based on carbon combustion are to be replaced in the future by environmentally friendly and CO2-neutral forms of energy delivery. It is the automotive industry that will once again pioneer the development of this dynamic new technology.

-Bernard Rzany

The significant increase in the number of devices, machines and even vehicles powered by batteries is forcing new developments in manufacturing technology and its automation, as well as the development of new manufacturing concepts. The first choice for the manufacturing processes of electrical components and batteries or rechargeable batteries is laser technology, especially laser bonding technology with its innovative devices and systems.

Less chipping and cracking.

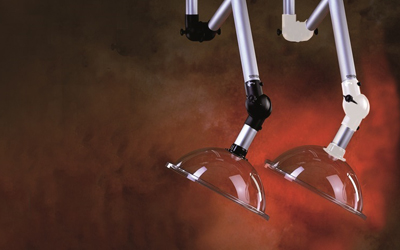

Innovative processes – such as welding using the optimal temperature distribution in the weld area, made possible by dual-fiber technology – are opening up entirely new possibilities in laser-based manufacturing processes. Precise joining, without cracking or splintering, of copper and aluminum materials as well as composite materials (such as SigmaClad) and even splinter-free welding of electromagnetic sheets1 is made possible by the so-called ARM laser technology. In this unique solution, two laser beams are guided coaxially from two optical fibers onto a laser beam focusing system – which can be a conventional laser welding head, a galvo mirror system or a newly developed focusing system called SmartWeld+. It is a welding head based on dynamic control systems of galwo mirrors.In order to achieve good absorption of the energy emitted from the laser on the metals to be welded, the laser radiation is introduced into optical fibers with very small diameters, on the order of 20 μm. At the focal point of the focusing optics (the diameter of the beam at the focal point is about 20-50 μm) there is a correspondingly high energy density, the disadvantage of which is the high temperature gradient generated in the welding seam from the edge to the center of the seam. It usually leads to severe spattering during welding, depending on the type of materials being joined. However, this disadvantage can be overcome by using adjustable energy in the outer ring of the ARM laser, with the positive effect of significantly reduced or completely eliminated spatter. Another positive effect of ARM technology is a significant reduction in the tendency for cracks to form. This is due to the process of preheating the weld area, which allows moderate energy application, but with the necessary high density of laser radiation, important to produce a deep laser joint, even of a variety of metal types. This technology makes it possible to weld copper busbars and join various materials, such as aluminum to copper and other combinations of metals.

Rys. 1. Rozkład promieniowania laserowego na dwa światłowody: wewnętrzny i zewnętrzny. Tutaj w centrum 100% mocy (energia spawająca). W światłowodzie zewnętrz-nym 40% mocy (energia nagrzewająca materiał).

Controlled energy emissions

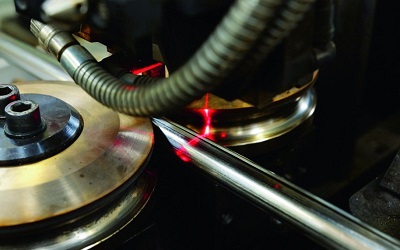

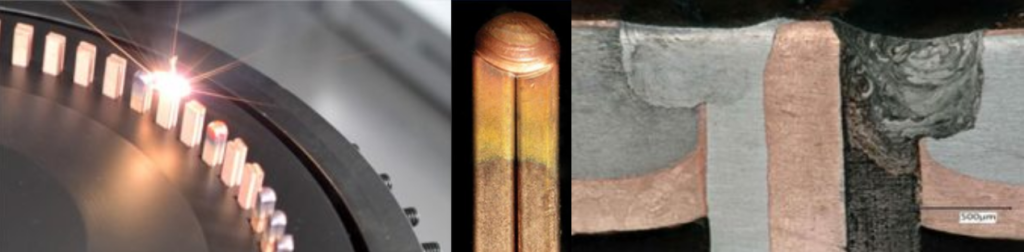

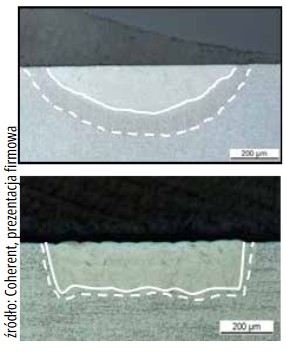

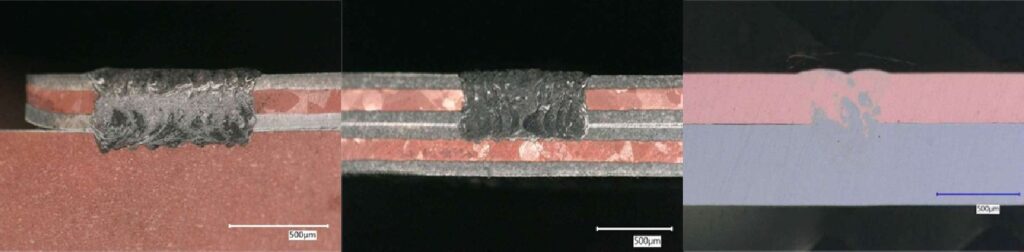

The joining of different materials, especially thin sheets, is also made possible by an optical focusing system that provides precise control of energy emission – this is the SmartWeld+ welding head. Similar results are obtained here as with the ARM laser. Thanks to the adjustable energy emission, the heat input to the welded parts (sheet metal) and the degree of melting of the weld are controlled, which enables a uniform welding depth and ensures a stable process (Figure 2). In this way, it is possible to successfully join not only materials of the same type, but also materials as diverse as copper (Cu) and aluminum (Al) or stainless steel, as well as composite materials, such as SigmaClad, which is a five-layer metal composite consisting of: nickel-plated surface, stainless steel, copper, stainless steel and again nickel-plated surface (Figure 3). Compared to conventional joining methods, the two described laser beam welding methods offer many advantages, including much higher welding speeds and thus much shorter cycle times per single welding point, line or surface. In addition, the laser beam as a tool is subject to almost no wear and tear – only the protective glass for the focusing optics is regularly replaced, as well as the laser beam diodes (every tens of thousands of hours). The advantage of these innovative welding processes is also better access of the welding tool to the joining area and contactless processing.In the production of mass-produced articles, it is important to ensure the quality of production. Laser welding systems allow online monitoring and documentation of welding parameters. Recently developed quality control systems even record the depth of remelting and are able to adjust it in real time.With the rapidly growing demand for efficient production equipment in the electrical industry, laser beam welding processes are sure to continue to grow. The next revolution in the transportation equipment sector is fast approaching. It is already known that in the future energy will also be produced from pure hydrogen – laser beam processing will also find its place here, which will contribute to increasing the efficiency of energy production from this carrier.

Rys. 2. Góra: Zgład ze standardowego połączenia spawanego okrągłą symetryczną wiązką laserową. Dół: Zgład z procesu spawania systemem SmartWeld+ ze zdefiniowanym polem przetopienia materiałów połączonych.

Fig. 3. The exact joints in the form of an overlap weld. Left figure: SigmaClad with copper. Melting depth of about 0.4 mm. Middle figure: SigmaClad materials with SigmaClad. The figure on the right shows a cross-section of the copper-stainless steel joint (battery cells).