- Types of processing: Structuring

- Worked materials: metals, glass, plastic

- Advantages: change in the surface properties of the material

- Industries: electronics, medicine, manufacturing industry

Modern technology is constantly advancing. Bringing innovative methods that make it possible to modify the surface of materials on a micro- and nanometer scale. Laser technology is one of the pioneering processes in this area. It allows a controlled and reproducible change in the structure of materials using a laser beam. This brings with it many new opportunities in fields such as nanotechnology, electronics, medicine, materials science, as well as broader industry and many others.

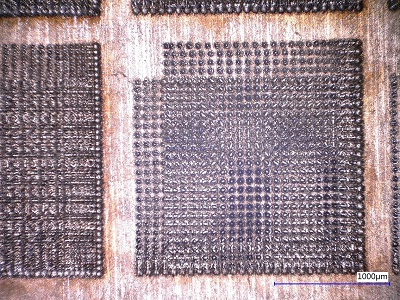

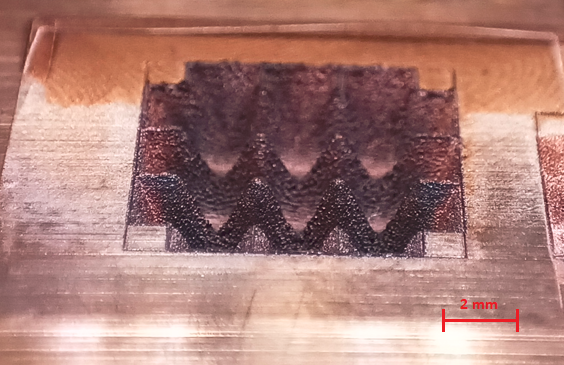

Photo Gallery

Structuring and its application

Laser structuring is a process in which a laser beam is precisely aimed at a material, making it possible to manipulate its physical and chemical properties on the micro and nano scales. Using different types of lasers, such as femtosecond, picosecond and nanosecond lasers, different structural effects can be achieved on the surface of a material. Depending on the laser parameters and material properties, processes such as ablation, controlled melting and cooling of the material can occur, leading to the generation of two- or three-dimensional structures.

Laser structuring of materials is of great importance in nanotechnology. One of the benefits is the improvement of mechanical, electrical and optical properties of materials. The creation of structures with specific geometries on metallic or semiconductor surfaces can lead to the appearance of plasmonic effects. These are used, for example, in increasing the absorption of solar radiation by photovoltaic cells.

Structuring - industries

In electronics, laser structuring can be used to process silicon wafers for advanced microprocessors and integrated circuits, as well as improve the properties of perovskites.

Another field eager to reap the benefits of laser structuring capabilities is medicine. Microstructures on implants improve their biocompatibility and tissue proliferation capabilities compared to material without such structure.

A synergy of laser cleaning with simultaneous structuring can be an excellent combination. Material prepared in this way has increased adhesion, so that a coating layer in the form of paint or varnish will bond more tightly to the material.

Another application of laser structuring can be the creation of hydrophobic coatings. Skillfully applying the structure to the surface of the material changes its wettability angle, so we can selectively change the properties of the material, for example, for the next manufacturing process, which may be the application of sealing layers.