- Support tool: system for measuring the transmissivity of plastics

- Laser: 980 nm

- Applications: laser welding of plastics

- Usage:Laboratories, quality departments, production lines with online measurement option, which enables continuous quality control.

What are transmissivity measurements and why are they used?

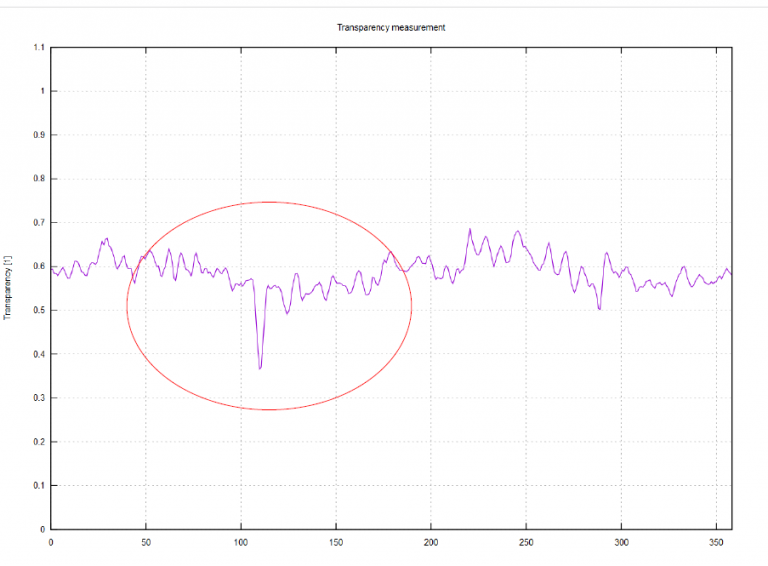

The transmission coefficient is a measure of how much light passes through a material. In industry, especially in laser welding, measuring transmissivity plays a key role in controlling the welding process and the quality of joining materials. Transmissivity in laser welding refers to the ability of a laser beam to penetrate a material and deliver the energy needed for welding.

Adequate transmissivity is essential to ensure effective joining of materials and to avoid undesirable phenomena such as burning, cracking or deformation. Too low a transmissivity can lead to incomplete welding, while too high a transmissivity can cause excessive energy absorption, which in turn can lead to excessive melting or burning of the material.

With precise transmissivity measurements, it is possible to achieve durable, strong and high-quality joints.

Our measurement system for transmission characteristics of plastic materials offers key parameters:

- Our system is precise, allowing you to get results with an accuracy of 0.01.

- The system is custom-designed to ensure complete customer satisfaction.

- Dedicated to symmetrical rotating parts

What are the advantages of using transmissivity measurements before the laser welding process?

- Minimal thermal stresses.

- Flexible, CNC-controlled and adjustable process.

- Laser welding without additional materials.

- Joining by forming one piece of plastic material.

- Internal welding without visible marks on the part surface.

- Small zone affected by heat.

- High quality and durability of the weld.

- Online quality control.