Application of CO2 Lasers in Industry: Advantages and Prospects

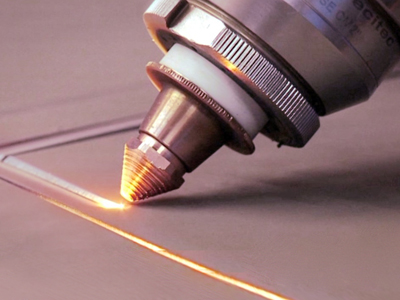

The CO2 laser, or carbon dioxide laser, is one of the most versatile and effective tools used in industry. In this article, we will discuss the applications of CO2 lasers, what they are and how they work, and the benefits they bring to various industries.