Knowledge base

Laser welding – advantages and disadvantages

Laser Cutting vs. Traditional Methods: When Is It Worth Investing in Modern Technology?

Previous

Next

Main Menu

Laser module for quasi-simultaneous welding EVO 0750

Laser class: 4 Wavelength: 980nm Laser power: do 400W Laser spot: 2,5mm Applications: welding of plastics The plastic welding module is designed for implementation

Plastic welding system – EvoWeld Mini

Laser class: 1 Wavelength: 980 nm / 1940 nm Laser power: 70 W – 200 W Processing area: 100 x 100 mm Applications: welding

Health and Safety Seminars

As specialists in the laser technology industry, we pay special attention to safety in working with lasers, including expanding knowledge and competence in our

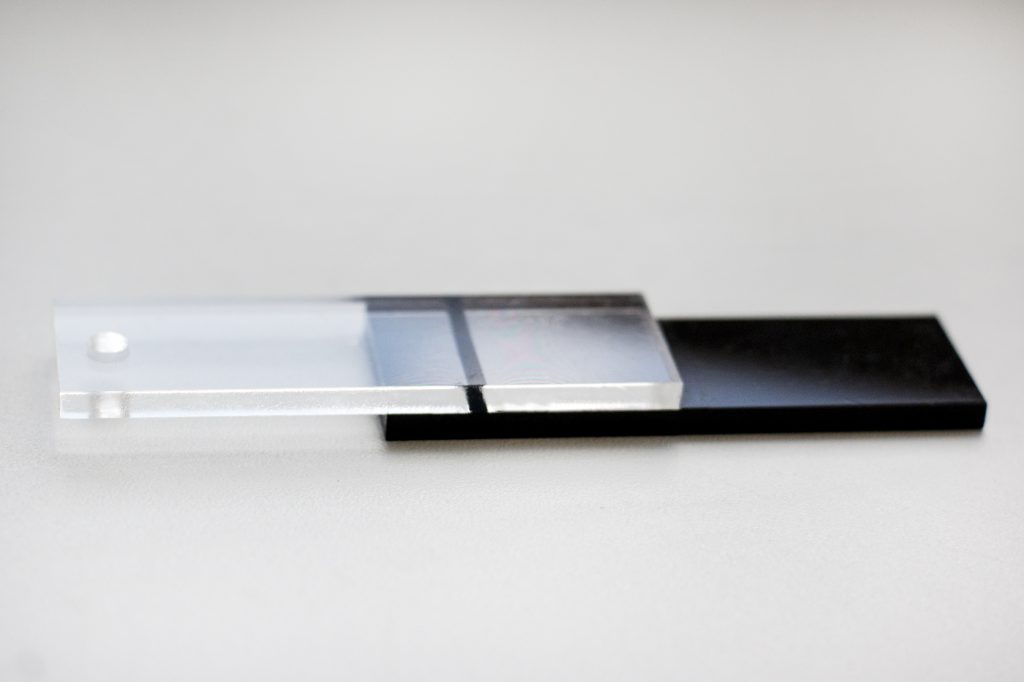

System for measuring the transmissivity of plastics

Support tool: system for measuring the transmissivity of plastics Laser: 980 nm Applications: laser welding of plastics Usage:Laboratories, quality departments, production lines with online

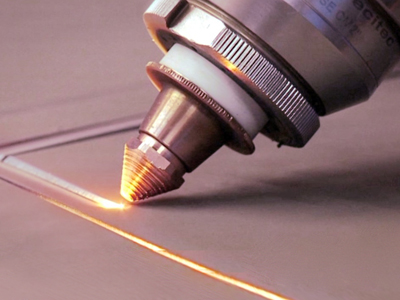

Laser cleaning

Types of processing: laser cleaning Material processed: metallic materials Advantages: high process speed Laser cleaning Laser cleaning is a modern method of vapourising unwanted

Eyewear and health and safety products for medicine and cosmetics

Type of equipment: goggles and safety equipment for medicine and cosmetics Scope of protection: direct and diffuse laser radiation in the full wavelength spectrum

Accessory equipment

Type of equipment: accessory equipment Scope of offer: eyewear and glazing fixtures Adventages: safe storage and care, time saving In order for purchased protective

Protective screens and shades

Type of equipment: protective screens and shades Range of protection: diffuse laser radiation Aplications: cutting, welding, drilling, marking, engraving, ablation, surface treatment Advantages: high